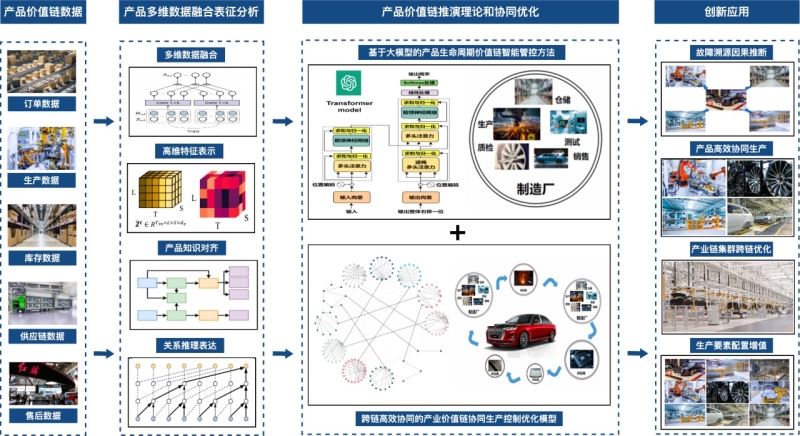

Recently, the national key research and development project "Multi-Dimensional Data Space and Service Theory for Product Lifecycle Value Chain in Manufacturing", led by Professor Xuan Song, Director of the Smart City Center at the Research Institute of Trustworthy Autonomous Systems(RITAS), has achieved a series of critical breakthroughs in the field of intelligent manufacturing. The project has successfully tackled core technologies of the "Manufacturing Brain," overcoming critical challenges in the deep collaborative optimization of complex manufacturing value chains. Led by Southern University of Science and Technology, in collaboration with Jilin University, Changchun University of Science and Technology, and China FAW Co., Ltd, the project has carried out nearly three years of joint efforts integrating industry, academia, research, and application. Through this collaborative approach, it has made breakthroughs in multiple key technologies related to product value chain data services and collaborative production, achieving a series of innovative results.

The project is closely aligned with China’s strategic priorities for high-quality development in the manufacturing sector. It tackles critical challenges commonly encountered in China’s manufacturing industry, including difficulties in integrating and sharing vast, complex data across the product value chain, low efficiency in coordinating intricate process workflows, and challenges in accurately identifying cause-and-effect relationships. The project has successfully addressed the theoretical challenges involved in constructing a multi-dimensional, collaborative data space service for the product lifecycle value chain. Its outcomes have been successfully implemented at factories operated by China FAW Co., Ltd.

Looking ahead, Professor Xuan Song’s team will leverage the research foundation established by the National Key R&D Program to intensify their focus on the critical demands within the national intelligent manufacturing sector. They aim to accelerate breakthroughs in the key core technologies of next-generation artificial intelligence to overcome “bottleneck” challenges in high-end manufacturing, while pioneering AI-driven pathways for cultivating new quality productive forces in the manufacturing.

Related reports: